Threaded Rivets by Specialinsert®

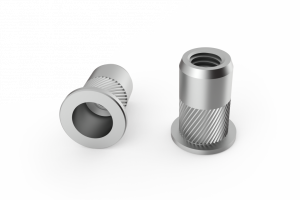

The Deform-Nut® deformable threaded tubular rivet by Specialinsert®, available in cylindrical, hexagonal or semi-hexagonal shank versions, allows you to obtain a thread on small thicknesses, in materials ranging from aluminum to steel, to plastic and composites , with a minimum thickness of 0.5mm, guaranteeing maximum hold and excellent aesthetic results.

The main areas in which it is used include the automotive, naval, transport, furniture and household electrical appliances sectors. The first choice in the automotive sector is also Deform-Ti®, the deformed threaded tubular rivet in titanium alloy which, due to its lightness and high resistance to traction, cutting and corrosion, is also widely used in the aeronautics, motorsport, nautical and chemical sectors: areas in which weight control is a priority as much as the ability to hold materials.

A new product, also patented, proposed by the company is the deformable tubular rivet with self-locking thread, in a cylindrical or hexagonal version, which provides a nylon ring at the end of the thread to rub the screw during assembly. For parts subject to vibrations, the most suitable alternative is Rubber-Nut, anti-vibration insert thanks to the vulcanized rubber coating and which has a threaded brass bush inside. Finally, in the case of applications on sandwich panels, often inefficient techniques in terms of time and costs are used, such as drowning resin or bonding of threaded bushes or tie rods.

To simplify and speed up the process, Specialinsert® has developed and patented the Deform-Nut TC/SC and TC/SC/1 systems, which allow you to create structural threaded fastenings on sandwich panels, in composite materials, carbon fiber and light alloy, through a mechanical and chemical double anchorage.

In fact, they consist of a deformable threaded tubular rivet with immediate mechanical fixing on the first skin of the panel, an insert in which an adhesive is subsequently injected into the honeycomb part for chemical fixing, carefully selected on the basis of compatibility with the receiving material. Once the glue has been deposited at the bottom of the rivet, the bush is screwed, for the TC/SC system, or grain, for the TC/SC/1 system, particularly suitable for thin panels.