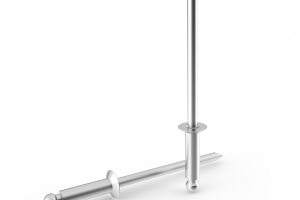

Blind Rivets by Specialinsert®

Finally, where the thickness of the two elements to be assembled varies, Specialinsert® provides wide-tightening rivets, with deformable body shape and size suitable to ensure optimal yield.

Ideal for applications on metal laminates or laminates in general, the blind rivets consist of a deformable body and a mandrel that is broken during riveting, applied with manual or pneumatic systems. When the nail inside the spindle is tractioned, it causes a deformation of the external body by fixing the insert into the receiving material, ensuring the assembly of the components.

To choose the most suitable rivet, it is essential to consider the combination and thickness of the materials, drill a hole of adequate diameter as well as assess the environment in which it will be used and the mechanical stresses to which it will be subjected. Based on specific uses, Specialinsert® offers different types of blind rivets. The standard solutions are used for the assembly of two elements, basically sheet metal, to ensure a fixed and static riveting.

Instead, we recommend the use of structural blind rivets in the case of installations with high mechanical stresses, where, once the mandrel is broken, part of the nail remains inserted in the body, thus ensuring a superior resistance to cutting and traction.

For environments where it is necessary to ensure good waterproofing of the components, watertight rivets are ideal, with rear part hermetically sealed (no-through hole). In other words, where the thickness of the two elements to be assembled is variable, Specialinsert® provides rivets with wide tightening, with deformable body shape and dimensions suitable to ensure optimal performance.