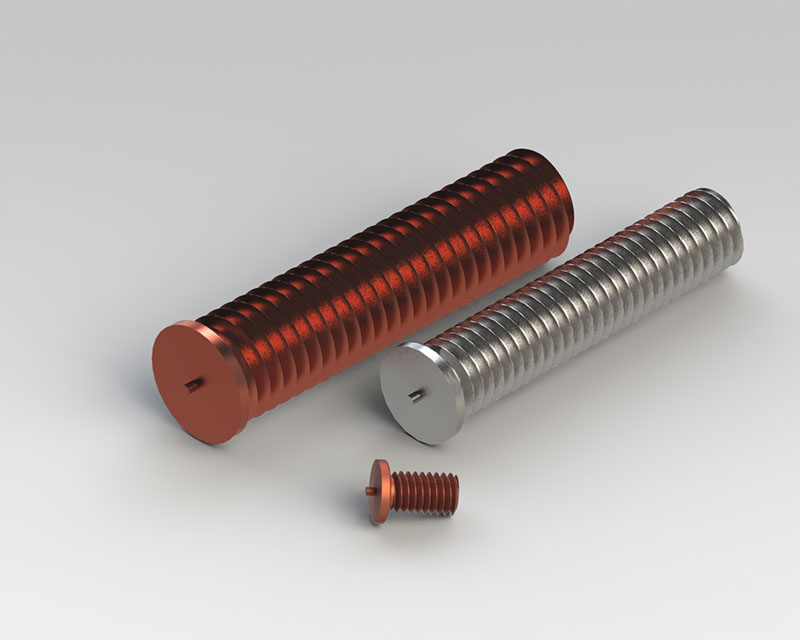

Welding Studs by Specialinsert®

The welding systems ensure a high-strength fixing, without drilling holes on the receiving sheet metal and are therefore an ideal solution for installations where a watertight seal is required.

For these applications, Specialinsert® proposes Sald-Stud, a threaded stud in steel or stainless steel, provided with a rounded-off striking step specially designed for condenser spark welding. Suitable for light carpentries and thin sheets, with clean and shiny surfaces, this welding process is activated by the passage of energy from the generator to the threaded stud whose trigger tip melts in contact with the receiving material, ensuring an instant connection to the sheet metal. For this laying technique, it is sufficient to have access to a single side of the sheet metal.

Among the techniques generally used for welding fasteners, there is also the voltaic arc procedure, which, through the fusion of the end of the stud and the receiving surface, immerses the stud in a casting bath, binding it to the sheet metal.

The terminal flange of the insert, larger in diameter than the thread, in addition to increasing the contact surface of the stud for greater seal, is specifically designed to prevent the arc from damaging the thread during the welding phase. A process that takes approximately one second, with variable times in relation to the diameter of the part to be welded.