The booming aerospace industry offers many opportunities for fastener manufacturers and suppliers. U.S. company Grand View Research Inc. estimates that the global satellite payload market will reach 21.8 billion by 2025, with an annual increase of 7.9 percent. This could be added to the commercial sector with the prospects of space tourism, promising exponential growth in the coming years, as well as the demands for communication and broadcasting services.

Fastening systems for the aerospace industry

Aerospace design requires fastening systems of the highest quality and precision. The rigorous standards required by such fasteners make them suitable for any precision fastening application. Put it simply, one of the reasons why quality must be extremely high is that satellites, probes, rockets, and other space objects beyond Earth’s atmosphere are unreachable for maintenance operations.

The aerospace industry has been using a variety of standard fasteners, including screws, nuts, rivets, studs, and special fastening systems. Such equipment and technologies are subjected to extreme conditions, with high pressures and temperatures due to leaving the Earth’s atmosphere or exposure to rocket fuel. Therefore, aerospace fasteners must undergo very rigorous tests that simulate space conditions on Earth.

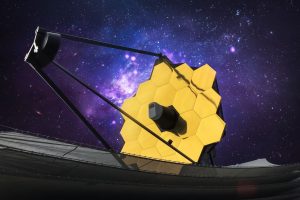

Recently, NASA had to delay the launch of the James Webb telescope due to fastening problems discovered during the final phase of testing. One particular test simulated the extreme sound vibrations associated with the launch: it was after this acoustic test that inspectors found a loosening of the fasteners used to secure the solar shield covers. But all is well that holds up well: launched on 25 December 2021, a few months later the Webb telescope sent back the first images of the most distant and ancient galaxies ever observed, as well as previously unseen shots of Jupiter and its satellites.

Aerospace fasteners: the main requirements

Moving back to aerospace fasteners, here are some of the typical specifications required of them:

- high resistance to corrosion, oxidation, and mechanical stress;

- reduced weight to optimize lift, i. e., the force that enables an aircraft to sustain itself in flight, and to minimize rocket fuel costs;

- ability to operate in extreme environments, subject to high pressure and temperature changes;

- self-sealing and self-locking capabilities to prevent pressure loss and loosening.

Aerospace fasteners: an overview of materials

As for materials, the most common among aerospace fasteners are:

- Steel and steel alloys, characterized by high strength and surface hardness. Their heaviness, however, can create some difficulties in the design and construction of aircraft and spacecraft, so great care must be taken when using them for aerospace parts and components. Stainless steel and alloy steels are the most popular types.

- Titanium, a viable alternative to light alloys in the construction of aerospace fasteners. Among its advantages are hardness, comparable to that of steel and alloy steels, relative lightness, and resistance to heat and cold.

- Superalloys or high-performance alloys, chosen for their ability to withstand the different types of stresses to which aerospace components are subjected. These types of materials offer high versatility and the ability to maintain structural and surface integrity in extreme environments.

The importance of co-design

As mentioned earlier, when it comes to aerospace fasteners, the industry does not always resort to customized solutions, but simulation tests make it possible to verify the tightness of fasteners at every stage of design. Communication between manufacturers and end users is an active part of the process: manufacturers must always be aware of the conditions under which their fasteners will be used.

A dedicated Field Engineer for the aerospace and aeronautical sectors is available for Specialinsert® customers. Through our technical support, we also offer two test laboratories dedicated to both the verification of existing products and the development of new prototypes. We want to make sure that even the most ‘out of the world’ project can become a reality.